Gary Horgan (CMSE Consultancy Manager at the Chris Mee Group) and his team are outlining the path for companies to ensure they are compliant with Part 8 “Explosive Atmospheres at Places of Work” of the Health, Safety & Welfare at Work (General Applications) Regulation 2007 in a series of focussed blogs.

- Blog 1, Explosion Accidents 2020

- Blog 2, Preparing for an Explosion Protection Document

- Blog 3, Summary of Legal Requirements

- Blog 4, What Are Explosions?

- Blog 5, Characteristics of Flammable Liquids, Gases and Vapours

In this latest blog of our series looking at explosion safety, we will be discussing some of the key flammable characteristics of dusts and powders that could pose an explosion hazard.

Understanding these characteristics of the flammable materials on your site is a crucial step in the development of an Explosion Protection Document, as without this information it is impossible to understand the explosion hazards which are present.

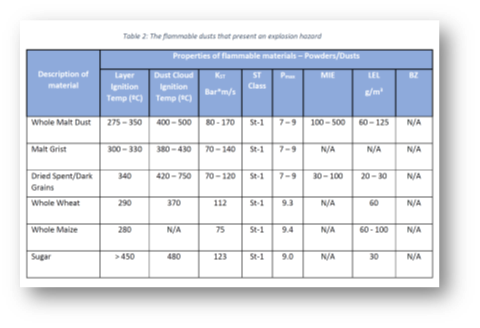

The table below is an example of dust and powder characteristics that would typically be included in an Explosion Protection Document; we will look at some of these in more detail below.

Unlike for flammable liquids and gases, these characteristics are often not listed on a Safety Data Sheet (SDS). For common materials, information is available from literature sources such as the GESTIS-DUST-EX database, which is published by the IFA in Germany and is available online. In other cases, the best option is to send samples for explosibility testing.

Lower Explosive Limit

As for the lower flammable/explosive limit for flammable liquids, vapours and gases as discussed in the previous blog, there is a lower explosive limit (LEL) for combustible powders and dusts. The concentration of dust/powder in air must be above the LEL for an explosion to occur.

For powders and dusts, this value is generally quoted in grams per cubic meter (g/m3); for many organic materials, the LEL is in the range of 10 – 50 g/m3.

In practice, establishing the potential concentration of a dust cloud is more difficult than the concentration of a flammable vapour cloud, and so this is often done in a more qualitative way, using previous experience and judgement.

Minimum Ignition Temperature

The minimum ignition temperature, as the name suggests, is the lowest temperature at which a combustible material will ignite. For combustible powders and dusts, there are often two separate ignition temperatures to consider:

- Dust cloud ignition temperature

- Layer ignition temperature (also referred to as the glowing temperature)

The dust cloud ignition temperature is the temperature at which a powder will ignite while existing as a dust cloud in air, whereas the layer ignition temperature is the temperature at which a powder will ignite while settled as a 5mm layer on a hot surface. These temperatures are often different, for example granulated sugar has a cloud ignition temperature of ~480 C, and a layer ignition temperature of ~450 C.

It is important to understand both of these ignition temperatures when considering the ambient temperature of your processes, as well as how hot surfaces may get in normal and fault scenarios (e.g. ovens, overheating bearings).

Kst, Pmax and ST Class

These parameters all provide information about how powerful an explosion could be if the dust/powder were to ignite.

- Kst is the maximum rate of the pressure rise, given in bar.m/s;

- Pmax is the maximum pressure that will be experienced during an explosion.

- ST class is one of four classes (St 0 – St 3), and is based on the Kst value, and gives an indication of the damage that could be caused by an explosion.

A material that has zero risk (Kst = 0 bar.m/s) of explosion is an St 0 dust. All other dusts have an explosion hazard. Even a St 1 dust could generate sufficient power to cause a flash fire, compromise containment on a piece of equipment, or blow out the walls of a building. Grains, Sugar, Coal, PVC, Flour, etc. are typically considered St 1 class dusts.

Dust Particle size

When comparing literature values to the material you have on site, it is important to take note of the particle size, particle size distribution, and moisture content. These properties can have a very large impact on how flammable and/or explosive a dust or powder may be. For example, finer powders have a greater surface area, and so may ignite much more readily. Particle size between 0.02 – 0.4mm are considered to pose an explosion hazard. Larger dust particles will be too heavy to stay suspended in air and form a dust cloud.

Burning Behaviour (BZ)

The BZ number for a material indicates whether and to what extent a fire started by an external ignition source can spread in deposited dust. It is based upon combustibility testing, and has the following definitions:

- BZ 1 – Does not catch fire

- BZ 2 – Catches fire briefly and extinguishes rapidly

- BZ 3 – Local burning without spread

- BZ 4 – Spread of a glowing fire

- BZ 5 – Spread of an open fire

- BZ 6 – Very rapid combustion

CMSE Consultancy provide a professional Health, Process, Explosion & Fire Safety Services.

If you require further information or assistance please contact us via email at info@cmse.ie, by phone at 021 497 8100 or start an instant chat with us via the chat box in the bottom right-hand corner of your screen.