Written by Occupli Safety Consultant Jake Bumpus

It is not unusual for some workplaces (such as R&D labs) to handle substances which have relatively little health and safety data available; by their nature, these facilities are often handling substances which are novel and so in-depth testing and characterisation has not yet been completed.

However, there are well-established methodologies available to occupational health and safety professionals and occupational hygienists in the pharmaceutical industry to make suitably conservative assumptions about the chemical hazards posed by a relatively novel substance, and hence what type of engineered controls are required to safely handle them.

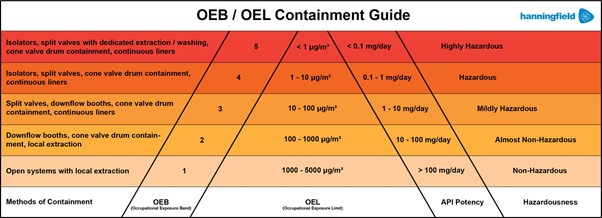

Variously called “Occupational Exposure Banding” (as described by NIOSH in the US), or “Control Banding” (the term used by the UK HSE), a banding approach can be used with relatively little detailed toxicological information to determine the required controls. Figure 1 below is a useful summary table which relates the methods of containment required to safely handle a substance, the associated Occupational Exposure Band, the Occupational Exposure Limit, Active Pharmaceutical Ingredient (API) potency, and overall hazard posed by the substance.

As an example, if a research and development facility was being used to handle a new API candidate substance, with a potency of 5 mg/day, then this would be classified as requiring an OEB of 3. To handle this substance safely, the types of engineering containment controls would include the use of split valves, downflow booths and continuous liners.

Despite a lack of detailed health and safety information being available, this type of methodology can be used to ensure that worker exposure to hazardous chemical agents is minimised and that the risk is kept as low as reasonably practicable.