ATEX Explosion Case Study

The Problem: HSA Inspection Identifies ATEX Issues

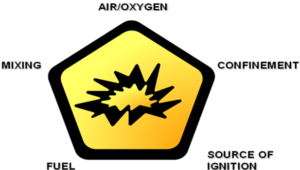

Occupli was contacted by a large manufacturing facility based in Co Kerry that uses a large amount of highly flammable solvents in their manufacturing processes. A recent Health & Safety Authority inspection at the facility highlighted the identification, management and control of explosive atmospheres as an area for review and improvement.

The Solution: An Explosion Protection Document (EPD) to Control and Manage Their Explosion Hazards

Occupli met with the client team for initial on-site meeting and preliminary review of the flammable substances used in the manufacturing operations on site. The client was advised that the site required the preparation of an Explosion Protection Document (EPD), as required under the Safety, Health & Welfare (General Application) Regulations, 2007, Part 8 Explosive Atmospheres at Places of Work, and this work was subsequently commissioned.

As part of the scope of project Occupli Consultancy undertook the following tasks:

- Prepared a schedule of the explosion properties of the flammable substances used

- Reviewed the existing technical & organisational measures in place to control and manage their explosion hazards and highlighted deficiencies in a schedule of recommendations

- Completed a Hazardous Area Classification exercise, in accordance with BS EN 60079-10-1; 2015, for the storage, manufacturing and waste handling/storage areas. Specific industry guidelines were also considered

- Prepared Hazardous Area Classification drawings for the manufacturing facility

- Conducted electrical and mechanical ignition risk assessments in the potential Hazardous Area Classification zones

- Prepared the Explosion Protection Document to demonstrate how their explosion hazards are controlled and managed

- Issued a risk prioritised schedule of practical and cost effective recommendations to ensure regulatory compliance

Once documentation was issued to the client each of the specific elements of the Plan were reviewed and explained to the client. Occupli Consultancy continues to support this client on an ongoing basis to ensure timely regulatory and best practice compliance.

The Benefits That Accrued from Working with Occupli

The benefits of the support and advice provided by Occupli were:

- The client adopted and demonstrated a systematic and risk based approach to the management of vehicular and pedestrian activities on site

- To ensure compliance with relevant regulatory and legal requirements

- Management demonstrating a strong commitment to providing a safe place to work for all stakeholders

- A reduction in the risk of an accident or incident that would lead to business interruption and commercial loss

ATEX Services Provided By Occupli

Occupli provides a top quality ATEX consultancy and support service to our clients nationwide. We have extensive ATEX experience and a proven track record in providing these services across many industrial sectors. Our ATEX consultants have both process and electrical safety expertise which makes our solutions both legally compliant and beneficial from the perspective of potential cost reductions and savings. Occupli work with clients to:

Occupli provides a top quality ATEX consultancy and support service to our clients nationwide. We have extensive ATEX experience and a proven track record in providing these services across many industrial sectors. Our ATEX consultants have both process and electrical safety expertise which makes our solutions both legally compliant and beneficial from the perspective of potential cost reductions and savings. Occupli work with clients to:

- Carry out the required ATEX risk assessments to identify and determine the necessary control measures

- Carry out a Hazardous Area Classification exercise for any location

- Assist with recommending and implementing additional control measures to reduce risk if required

- Generate your EPD to outline the control measures, both physical and organisational, in place and demonstrate compliance with the Safety, Health and Welfare at Work (General Applications) Regulations 2007

- Assist with the generation of zoning and hazardous area layout drawings

For more information on the Occupli ATEX and process safety services please visit Occupli Consultancy or Occupli Training

Invest in your future with our industry-leading training. Enroll today and take the first step toward a brighter tomorrow!